Management Team

Sealmatic – Arrival Of The Fittest

Umar A K Balwa & Hanif S Chaudhary have dedicated themselves to the field of fluid sealing technology since 1989 and have introduced fresh ideas and innovative designs for heavy duty engineered mechanical seals. With over three decades of experience, they have helped customers to find the best solutions to solve critical sealing challenges. Customers, globally, rely on their expertise, for they provide an unmatched combination of products, engineering and aftermarket services.

Umar A K Balwa

Managing Director

Hanif S Chaudhary

Executive DirectorEvolution of the mechanical seal market and the major factors driving its growth

The mechanical seal market has been predominantly dominated by international players over the last five decades. The technology employed in the manufacture of mechanical seals requires high precision designing and production, which was not available in the nascent stage. Over the years, the capabilities of the industry improved dramatically and paved way for the induction of state-of-the-art technology in all the industrial fields, viz oil & gas, refinery, power, petrochemical, chemical, pharmaceutical, fertilizer, pulp & paper, shipping, aerospace etc, thus creating huge demand for high precision mechanical seals. Mechanical seals are designed to prevent leakage of exotic and hazardous media into the environment. Consequently, increasingly stricter legislations made it mandatory for the industrial plants to employ mechanical seals for all their rotary equipments. Way back in the early 1980s, the size of the mechanical seal market was merely USD 300 Million and today the same has grown exponentially to USD 3.5 Billion. The core sectors of the world economy are electricity, steel, refinery products, crude oil, coal, cement, natural gas and fertilizer. These sectors have a major impact on the world economy significantly and this will be the biggest driver for growth in the mechanical seal industry.

Major expectations of customers from sealing technology companies and how Sealmatic meets their expectations

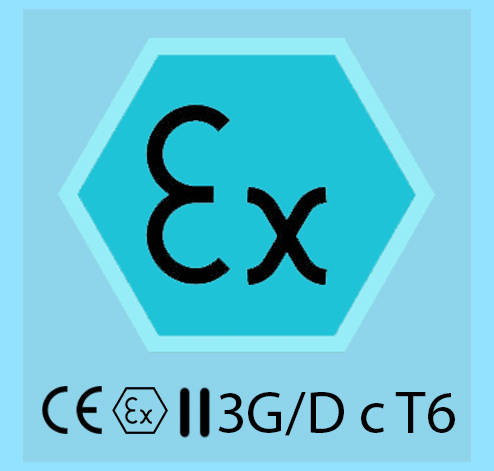

The major expectations of customers in this field are reliability, application know how and quick after sales & service. The mechanical seal industry is highly competitive technically. It demands a proven track record before one serves a customer’s application; hence know how to design a mechanical seal for a particular application is of paramount importance. Every mechanical seal produced is tailor made to suit the individual requirements of the customers. We are geared up and in fact the only domestic company which has invested huge amounts in R & D, Designing, Quality Control & Production. We have a dedicated team of 26 engineers who are employed for the sole purpose of designing individual solutions for customers globally. We are proud to state that we are the only Indian company which has the distinction of API Q1, ATEX & EU FDA certification for mechanical seals. Furthermore, as a domestic mechanical seal company, we are the only one that employs FEA & CFD for hardcore design and development of mechanical seals. From our experience in this field of over 32 years, our customers’ benefit from the enormous data that we bring to the table in terms of application know how, trouble shooting and failure analysis. This is the key to success in this highly competitive business.

Sealmatic's position in the field of industrial sealing technology

We enjoy excellent position in this market, our range of mechanical seals is exported to over 45 countries and is as well accepted as the big names of the industry. Domestically we are second to none in our offerings; we provide a comprehensive package to our customers globally, right from the selection of mechanical seals to the installation and training of the personnel at the end user premises. Due to the knowledge and application-based solutions we provide for critical equipments, we are the preferred vendor for various projects globally in the core industrial sector.

Major factors that set Sealmatic apart from other players in this segment

The Mechanical seal industry is highly competitive. It requires huge amounts of time, money and energy to reach a certain level. When we started out in 2011, we consciously made efforts to set up our plant to match international standards and specifications, not only in terms of employing hardware and software, but also by implementing very high international standards and a highly trained team. We are proud to state that we have more than 100 visits from international customers to our premises and all of them have simply defined us as a – "state of the art international facility." Moreover, if we compare ourselves with other domestic players, though we would not like to do so, the answer to this question would earnestly be that we have marched miles ahead of the domestic competition. We have got all the certifications in place which no other domestic manufacturer has, viz: API Q1, ATEX, FDA etc. Also if we consider R & D, we have invested in state of the art test rigs meeting API 682 standards. The investment in these test rigs is huge, sometimes surpassing the cost of a small mechanical seal company. We have built in capabilities of FEA & CFD, unlike any other company in India in our field. We have tools such as MSD (Mechanical Seal Dictionary), SSG (Seal Selection Guide), AKH (Application Know How) and many others which have catapulted Sealmatic to the big league of international players. We are perceived and respected globally as a high-quality mechanical seal company.

Sealmatic has been providing heavy-duty mechanical seals that offer innovative and tailor-made sealing solutions

As mentioned earlier, the business of mechanical seals entails application know how, which comes through years of varied experiences in this technically competitive industry. We have devoted over 32 years in this high-octane business, which requires out of the box thinking in order to provide solutions for very difficult and complex sealing applications. Our specialty lies in designing and providing heavy duty mechanical seals for pumps, compressors, agitators and other rotary equipments. Applications where the pressure rating exceeds 100 kg/cm2, temperatures in excess of 350 degree Celsius, slurry content of very high level, media with high viscosity and so on, have been designed over the years and developed as niche products to meet the above demanding applications. These are not only difficult to design and produce but it is equally challenging to install a suitable mechanical seal in the rotary equipment with such applications. This has been achieved from the rich data bank that we have assimilated in the last 32 years, which allows us to match such demanding application to the work that we have done in the past. Plus we employ the best of raw materials, which are imported from Germany, USA and the UK. We do not compromise on the metallurgy. Our heavy duty mechanical seals find applications in oil & gas, offshore platforms, pipe line booster pumps, heavy duty slurry pumps, high pressure agitators in chemical plants, high temperature rotary equipments in refineries and many more such varied applications.

Sealmatic's 30 years of legacy which has been constantly driving its growth with the challenging needs of superior sealing technology

Our journey in this business started in 1989 as a small enterprise with 200 sq mt of premises and a handful of 8 employees. Today we are housed in one of the most modern manufacturing facilities in India and can be ranked as a global player. Our journey coincidentally has been published by the company, the link for the same is - https://www.sealmaticindia.com/once-a-sealman-always-a-sealman.php Over the years Sealmatic has become synonymous to mechanical seals with deliveries to more than 45 countries. The modern plant of Sealmatic has grown exponentially since the 220 square meters it was at its nascent stage. Above all, every colleague is proud to be a part of this journey and the company. Anything more we add here about a company such as Sealmatic, which is growing every day will be premature. Sealmatic is the sum total of the efforts of all the people associated with it and a vision that the Sealmatic team shares. It's proven to us that a dream that is pursued with dedication earns the right to be called a vision. To future generations we would like to say that a seed sown via a relatively obscure company called A K Engineering proves to us that the name of a company can change over the years, as well as the hands running it, but its goals remain intact. We were given the privilege of watering this seed and nurturing it to its full potential, a process that is ongoing, but we trust that when its heirs enjoy the fruits they will remember where it all began. The field of mechanical seals is a dynamic, challenging and highly competitive arena. Every new application invites innovation and demands solutions. The subject involves physics, chemistry, mathematics and most importantly common sense. We developed an abiding respect for the mechanical seal business. It is a business that is critical to every industry. A mechanical seal is a vital component of rotary equipments. It employs our personal philosophy - if you set the small things straight, the big things will fall into place.

Future roadmap for Sealmatic

Long-term business success depends, above all, on the quality of the team providing the leadership, direction, and vision. The future of Sealmatic is to be in the forefront of the mechanical seal industry in the global arena. We already make deliveries to more than 45 countries and we aim to be physically present with our sales and service centres in every continent. We want to be the preferred choice when it comes to mechanical seals with various customers globally. We are continuously investing into highly trained manpower, the best of software and hardware and also imbibing the latest technology available to improve our designs and processes. In short, we are investing in the future. Sealing technology from Sealmatic demonstrates a very high level of reliability, safety and maximum cost-effectiveness. Our outstanding reputation for designing and engineering customized solutions is globally recognized. We partner with our customers and keep their operations safe and controlled.