Chemical & Petrochemical

Typical Applications

Agitator Bead Mill

Agitator Bead Mills are engineered to manufacture lighter, smaller, more-resilient and stronger materials in a versatile, high-energy, high-flow system design. Agitator Bead mills are basically employed to grind organic as well as inorganic solids by a process of wet crushing method with added liquids. In modern times, Wet Crushing Method is an environmentally sound process focusing in continuous, high-speed, heavy-duty enclosed type Agitator Mills with freely moving grinding medium.

Seal Type: UFR-D/70

| Media | Lacquer Production |

| RPM | 725 |

| Temperature | 650 C |

| Pressure | 3 Bar |

Chemical Pump

Chemical pumps are employed to transfer chemicals and are designed to be resistant to corrosive and abrasive industrial liquids such as fuel, paint, bleach, solvents, etc. Chemical pumps can be either centrifugal pump or a positive displacement pump depending on the specific application.

Seal Type: U700N

| Media | Aromatic Compounds |

| RPM | 1500 |

| Temperature | 200 C |

| Pressure | 14 Bar |

Eccentric Screw Pump

Eccentric Screw Pump can handle liquids with different viscosity levels and chemical properties. These pumps have a precision mechanized single external helix metallic rotor and double internal helix elastomer stator.

Seal Type: UG100/43

| Media | Sulphide Slurry |

| RPM | 2750 |

| Temperature | 900 C |

| Pressure | 6 Bar |

Gear Pump

Gear pumps are widely employed in chemical installations to pump high viscosity fluids, it processes the meshing of gears to pump fluid by displacement. Gear pumps are positive displacement or fixed displacement, they pump a constant amount of fluid for each revolution.

Seal Type: U700N/35

| Media | Printing Ink |

| RPM | 3500 |

| Temperature | 400 C |

| Pressure | 12 Bar |

Glass Lined Reactor

The glass lined surfaces of the Glass Lined Vessel are hard wearing and polished during the manufacturing process, making them easily cleanable. This, in turn, makes the surfaces inherently beneficial at avoiding cross contamination in batch processing applications.

Seal Type: U164-KL-D/100

| Media | Pharmaceutical Products |

| RPM | 41 |

| Temperature | 1800 C |

| Pressure | 4 Bar |

Thin Film Evaporator

Thin-film or thin-layer evaporators have been developed to purify temperature sensitive products by evaporation in the chemical process industries. The solution is a thin film of the liquid product on the inner side of a vertical evaporation pipe which is generated by a rotating wiper system.

Seal Type: U154 KL-D/80

| Media | Acrylic Ester |

| RPM | 2 m/s |

| Temperature | 1250 C |

| Pressure | 6 Bar |

Chemical Reactor

Chemical reactors are employed for converting the feedstock into the desired product. Generally, reactors are selected that will meet the requirements imposed by the reaction mechanisms, rate expression and the required production capacity. An important factor in reactor operation is the outlet degree of conversion. Operating conditions such as temperature, pressure, and degree of agitation are related to the most economic operation.

Seal Type: BSHL-D/125

| Media | Nickel Ammonium Sulphate |

| RPM | NA |

| Temperature | 2200 C |

| Pressure | 38 Bar |

Rotary Piston Pump

A rotary piston pump is a form of hydraulic pump. The working pistons extend in a radial direction symmetrically around the drive shaft. These kinds of piston pumps are characterized by high efficiency and high pressure.

Seal Type: U740-D/65

| Media | Viscous Media |

| RPM | NA |

| Temperature | 600 C |

| Pressure | 12 Bar |

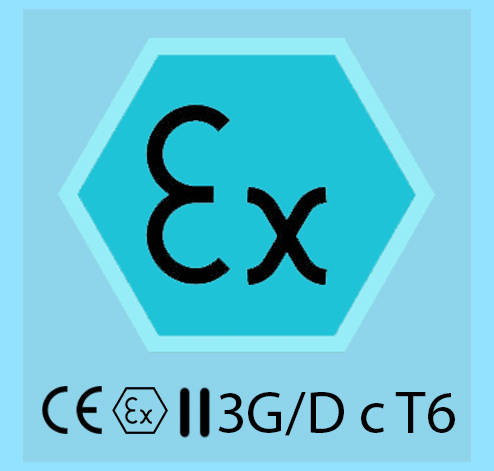

Chemical & Petrochemical

The materials used in the chemical/petrochemical industry need to be capable of coping with the large array of media, many of them explosive or toxic and others which could become when mixed. An increased awareness of environmental risks calls for a maximum reliability and operational safety, especially from sealing systems. Against this background, the sealing systems used in applications involving what are in many cases explosive, toxic or aggressive media have to ensure optimum tightness. On the other hand they should also help optimize processes and thus be of advantage where the economic aspects are concerned as well. From non-critical sealing points – for which standard solutions are deployed – right through to highly complex system solutions required where particularly difficult operating conditions are concerned.